Mabhura idambudziko rakajairika mukugadzirisa simbi, sekuchera, kutenderedza, kugaya, uye kucheka simbi simbi...

Imwe yenjodzi yemaburrs ndeyekuti ari nyore kucheka!Kuti ubvise burrs, kechipiri oparesheni inonzi deburring inowanzodiwa.3 kubvisa uye kumucheto kupedzisa kweiyo chaiyo zvikamu zvinogona kuverengera 30% yemutengo wechikamu chakapedzwa.Zvakare, sekondari kupedza mashandiro kwakaoma kuita otomatiki, saka maburrs anonyatsova dambudziko rinonetsa.

Kugadzirisa seiBURRS

1 Manual deburring

Iyi ndiyo nzira yakajairika uye inowanzoshandiswa, kushandisa mafaira (manual mafaira uye pneumatic mafaira), sandpaper, bhandi sanders, kukuya misoro, nezvimwewo sezvishandiso zvekubatsira.

Disadvantages: Mari yebasa inodhura, kushanda zvakanaka hakuna kunyanya, uye zvakaoma kubvisa makomba akaomarara.

Zvinhu zvinoshanda: Izvo zvinodiwa zvehunyanzvi zvevashandi hazvina kukwirira zvakanyanya, uye inokodzera aluminium alloy die castings ine madiki maburrs uye yakapusa chigadzirwa chimiro.

2 Die deburring

Deburring inoitwa nekushandisa dhizaini inofa uye punch.

Zvakaipa: Inoda imwe huwandu hwekufa (yakaoma kufa, yakanaka kufa) mutengo wekugadzira, uye ingangodawo kugadzira kufa kwekufa.

Zvinhu zvinoshandisika: Inokodzera aluminium alloy die castings ine nyore kupatsanura nzvimbo, uye kushanda nesimba uye deburring mhedzisiro iri nani pane iyo yebasa remaoko.

3 Kukuya nekubvisa

Rudzi urwu rwekubvisa runosanganisira vibration, sandblasting, rollers, nezvimwe, uye parizvino rinoshandiswa nezvinomera zvinofa.

Zvakaipa: Pane dambudziko rekuti kubviswa hakuna kuchena zvakanyanya, uye inotevera manyorerwo ekugadzirisa masara maburrs kana dzimwe nzira dzekubvisa dzingadikanwa.

Zvishandiso zvinhu: zvakakodzera diki aluminium alloy die castings nemabhechi makuru.

4 Frozen deburing

Shandisa kutonhora kukurumidza kumisa maburrs, uye wobva wapfapfaidza projectiles kubvisa maburrs.Mutengo wemidziyo inenge 200,000 kana 300,000;

Zvinhu zvinoshanda: Inokodzera aluminium alloy die castings ine diki burr madziro ukobvu uye vhoriyamu diki.

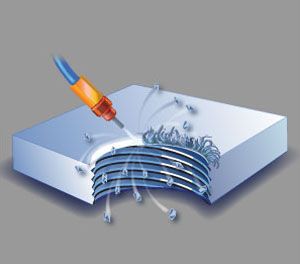

5 Kupisa kuputika kwemhepo

Iyo inonziwo thermal deburring, kuputika deburring.Nekuunza imwe gasi rinopfuta muchoto chemidziyo, uyezve kuburikidza nekuita kweimwe midhiya uye mamiriro, gasi rinoputika pakarepo, uye simba rinogadzirwa nekuputika rinoshandiswa kunyungudutsa nekubvisa burr.

Kukanganisa: midziyo inodhura (mamiriyoni emadhora), yakakwirira yehunyanzvi zvinodiwa pakushanda, kuderera kwehunyanzvi, mhedzisiro (rusting, deformation);

Zvinhu zvinoshandisika: Inonyanya kushandiswa mune dzimwe nzvimbo dzepamusoro-chaizvo, senge mota uye aerospace nemazvo zvikamu.

6 Deburring yemuchina wekunyora

Mutengo wemidziyo hauna kudhura zvakanyanya (makumi ezviuru).

Zvinhu zvinoshanda: Inokodzera nzvimbo yakapusa chimiro uye yakapusa uye yakajairwa deburring chinzvimbo.

7 Kubvisa makemikari

Uchishandisa iyo musimboti we electrochemical reaction, zvikamu zvakagadzirwa nesimbi zvinhu zvinogona kungozvigadzirisa uye zvakasarudzwa kubviswa.

Zvishandiso zvinoshandiswa: zvakakodzera kune maburrs emukati akaoma kubvisa, akakodzera mabhuru maduku (ukobvu pasi pe7 waya) yezvigadzirwa zvakadai semitumbi yepombi uye miviri yevhavha.

8 Electrolytic deburring

Iyo electrolytic machining nzira yekubvisa aluminium alloy die-casting burrs ne electrolysis.Electrolytic deburring yakakodzera kubvisa maburrs muzvikamu zvakavanzika zvealuminium alloy die castings, maburi emuchinjikwa kana zvikamu zvine maumbirwo akaomarara.Kubudirira kwekugadzira kwakakwira, uye nguva yekubvisa kazhinji ingori mashoma mashoma kusvika kumakumi emasekonzi.

Zvakaipa: Iyo electrolyte inoora kune imwe nhanho, uye padyo neburr yezvikamu zvakare inoiswa pasi pe electrolysis, iyo nzvimbo inorasikirwa nekupenya kwayo kwepakutanga, uye kunyange kukanganisa kurongeka kwedimensional.Iyo aluminium alloy die-casting inofanira kucheneswa uye kuvharidzirwa-kuvharwa mushure mekubvisa.

Zvinhu zvinoshandisika: Yakakodzera kubvisa magiya, matanda ekubatanidza, miviri yevharuvhu uye crankshaft oiri ndima maburi, pamwe nekutenderedzwa kwemakona akapinza.

9 High-pressure water jet deburing

Ichishandisa mvura sesvikiro, inogona kushandisa simba rayo rekukurumidza kubvisa maburrs uye kupenya kunogadzirwa mushure mekugadzirisa, uye panguva imwe chete, inogona kuzadzisa chinangwa chekuchenesa.

Cons: midziyo inodhura

Zvinhu zvinoshanda: zvinonyanya kushandiswa mumoyo wemotokari uye hydraulic control masisitimu emakina ekuvaka.

10 Ultrasonic deburring

Conventional vibration grinding yakaoma kubata nemaburrs semaburi.Iyo yakajairwa abrasive kuyerera machining process (mbiri-nzira kuyerera) inosundira iyo abrasive kuburikidza maviri vertically akatarisana abrasive masilinda kuti iite ichiyerera ichidzoka nekudzoka mugero rakaumbwa neworkpiece uye fixture.Kupinda uye kuyerera kweabrasive kupinda uye kuburikidza nechero nzvimbo inorambidzwa inoburitsa abrasive maitiro.Iyo extrusion pressure inodzorwa pa7-200bar (100-3000 psi), yakakodzera kune dzakasiyana siyana uye dzakasiyana kutenderera nguva.

Zvinhu zvinoshanda: Inogona kubata 0.35mm microporous burrs, hapana yechipiri burrs inogadzirwa, uye hunhu hwemvura hunogona kubata yakaoma chinzvimbo burrs.

11 Abrasive flow deburring

Conventional vibration grinding yakaoma kubata nemaburrs semaburi.Iyo yakajairwa abrasive kuyerera machining process (mbiri-nzira kuyerera) inosundira iyo abrasive kuburikidza maviri vertically akatarisana abrasive masilinda kuti iite ichiyerera ichidzoka nekudzoka mugero rakaumbwa neworkpiece uye fixture.Kupinda uye kuyerera kweabrasive kupinda uye kuburikidza nechero nzvimbo inorambidzwa inoburitsa abrasive maitiro.Iyo extrusion pressure inodzorwa pa7-200bar (100-3000 psi), yakakodzera kune dzakasiyana siyana uye dzakasiyana kutenderera nguva.

Zvinhu zvinoshanda: Inogona kubata 0.35mm microporous burrs, hapana yechipiri burrs inogadzirwa, uye hunhu hwemvura hunogona kubata yakaoma chinzvimbo burrs.

12 Magnetic deburring

Magnetic grinding ndeyekuti pasi pekuita kwesimba remagineti rakasimba, magineti abrasives akazadzwa mundima yemagineti anorongedzerwa negwara remagineti mitsara, adsorbed pamagineti pole kuti agadzire "abrasive brushes", uye anogadzira imwe kumanikidza pamusoro pebasa rekushanda, uye magnetic poles ari kutyaira "abrasives".Ipo bhurashi richitenderera, rinochengeta imwe gap uye rinofamba nepamusoro peiyo workpiece, kuitira kuti uone kupera kwechiso chebasa.

Zvimiro: yakaderera mutengo, yakafara kugadzirisa siyana, nyore kushanda

Maitiro ekugadzirisa zvinhu: guyo, simba remagineti, kumhanya kwebasa, nezvimwe.

13 Robot kugaya unit

Nheyo yacho yakafanana nekugadzirisa kwemaoko, kunze kwekuti simba rinoshandurwa kuita robhoti.Nerutsigiro rwehunyanzvi hwekugadzira uye simba rekudzora tekinoroji, kuchinjika kugaya (kuchinja kwekumanikidza uye kumhanya) kunoonekwa, uye zvakanakira kubvisa marobhoti zvakatanhamara.

Kuenzaniswa nevanhu, marobhoti ane hunhu: kuvandudza kushanda zvakanaka, kuvandudzwa kwemhando, uye kudhura kwakanyanya

Burrs muSpecial Challenge Milled Parts

Muzvikamu zvakagayiwa, deburring yakanyanya kuoma uye inodhura, sezvo akawanda maburr anoumbwa munzvimbo dzakasiyana dzehukuru hwakasiyana.Apa ndipo pakusarudza iyo chaiyo maitiro paramita kudzikisa burr size inotonyanya kukosha.

Nguva yekutumira: Sep-29-2022