Muchigadziro chekucheka, nekuda kwesimba rekucheka, rusvingo rwakaonda rwuri nyore kukanganisa, zvichiita kuti ellipse kana "chiuno" chiitiko chine zviduku zvepakati uye zvakakura.Uye zvakare, nekuda kwehurombo hwekupisa kupisa panguva yekugadziriswa kwematehwe-akakomberedzwa mabhomba, zviri nyore kugadzira thermal deformation, iyo yakaoma kuve nechokwadi chekugadzirisa kunaka kwezvikamu.Zvikamu zvinotevera hazvisi zvakaoma kusungirira, asiwo zvakaoma kugadzirisa.Naizvozvo, yakakosha yakaonda-yakakomberedzwa sleeve uye inodzivirira shaft ichagadzirwa.

Process analysis

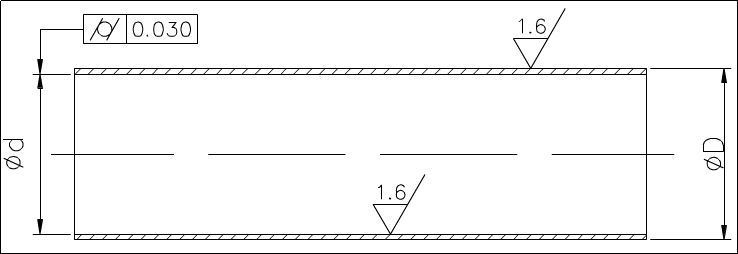

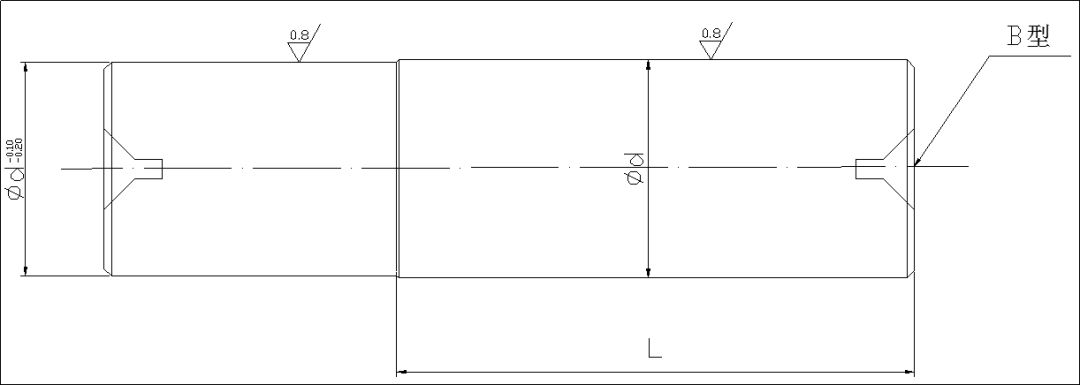

Zvinoenderana nezvinodiwa zvehunyanzvi zvinopihwa mukudhirowa, iyo workpiece inogadziriswa nesimbi isina musono pombi, uye hutsinye hwepamusoro hwegomba remukati uye madziro ekunze ndeye Ra1.6 μ m.Inogona kuonekwa nekutendeuka, asi cylindricity yegomba remukati ndeye 0.03mm, izvo zvinoda zvakanyanya zvinodiwa zvezvikamu zvakatetepa-zvakakomberedzwa.Mukugadzirwa kwakawanda, nzira yekugadzira yakaoma sezvinotevera: kuvharika - kurapwa kwekupisa - kutendeuka kwekupedzisira kumeso - kutenderedza denderedzwa - kushandura gomba remukati - kuongororwa kwemhando.

"Inner hole machining" maitiro ndiyo kiyi yekutonga kwemhando.Zvakaoma kuona 0.03mm silinda kana uchicheka gomba remukati regoko risina cylindrical nhete madziro.

Makiyi matekinoroji ekutenderedza makomba

Iyo yakakosha tekinoroji yekutendeuka maburi ndeyekugadzirisa matambudziko ekuomarara uye chip kubviswa kwemukati gomba kushandura maturusi.Kuti uvandudze kuomarara kwechishandiso chemukati chegomba, matanho anotevera anofanira kutorwa:

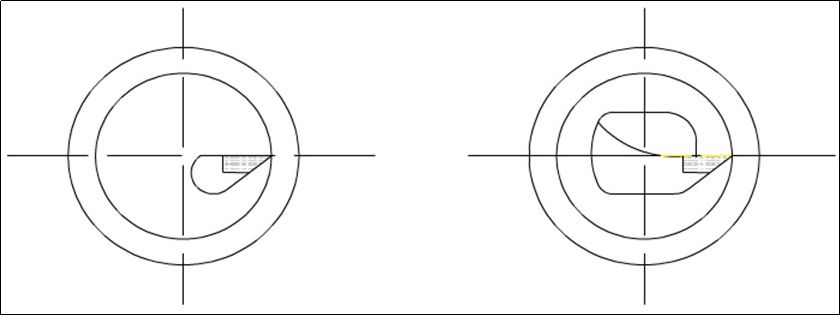

1) Wedzera nzvimbo ye-cross-sectional yechibatiso chekushandisa zvakanyanya sezvinobvira.Kazhinji, muromo wemukati wegomba rekushandura mudziyo unowanikwa pamusoro pechibatiso chekushandisa, saka chikamu chechikamu chemubato wechombo chiri pasi pe1/4 yechikamu chegomba, sezvakaratidzwa mumufananidzo unotevera.Kana iyo muromo wemukati wegomba rekushandura mudziyo uri pamutsara wepakati wechibatiso chekushandisa, chikamu chechikamu chemubato wechishandiso mugomba chinogona kuwedzerwa zvakanyanya, sezvinoratidzwa mumufananidzo unotevera.

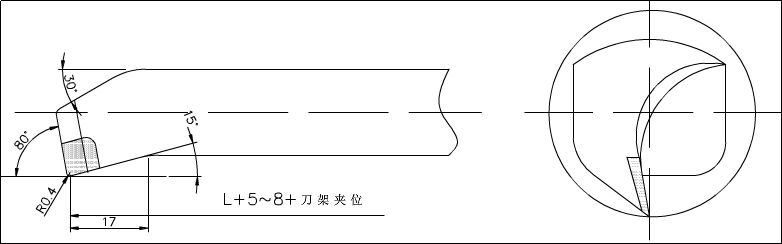

2) Hurefu hwakareba hwechibatiso chekushandisa huchave 5-8mm kureba kupfuura kureba kwechishandiso kusvika pazvinobvira kuwedzera kuomarara kwechishandiso chekushandisa uye kuderedza kudengenyeka panguva yekucheka.

Gadzirisa dambudziko rekubvisa chip

Inonyanya kutonga nzira yekucheka kuyerera.Maturusi ekutenderedza anoda kuti chip chiyerere kumusoro kuti chigadzirwe (mberi chip).Naizvozvo, shandisa iyo yemukati gomba yekutenderedza chishandiso ine yakanaka kumucheto kurerekera, sezvakaratidzwa mumufananidzo unotevera.

Mukuita kutendeuka kwakanaka, iyo chip inoyerera inodiwa kurerekera kumberi chip kwakananga pakati (chip kubviswa panzvimbo yegomba).Nokudaro, kuchenjerera kunofanira kubhadharwa kune nzira yekukuya yekucheka kwekucheka paunenge uchipinza chombo.Iyo chip yekubvisa nzira inofanirwa kutevedzera yakarerekera arc mberi.Sezvinoratidzwa mumufananidzo uri pazasi, yazvino M-mhando yakanaka inoshandura chishandiso alloy YA6 ine yakanaka kukotama simba, kupfeka kuramba, kusimba kwekuita, kunamatira nesimbi, uye tembiricha kuramba.

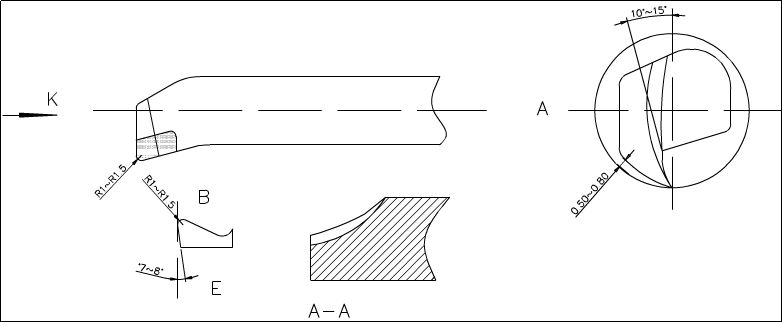

Munguva yekugaya, maererano nearc yekugadzirisa (pamwe nearc yezasi yemudziyo wezasi), kona yepamberi inotenderedzwa kune arc angle ye10-15 °, uye kona yekumashure ndeye 0.5-0.8mm kubva pamadziro.Kucheka kumucheto kwekona ye c ndiyo § 0.5-1 mune k kutungamira uye R1-1.5 panzvimbo B pamwe chete nechekuputi.Yechipiri yekumashure kona inokodzera kugaya kusvika 7-8 °.Gaya point AA pamucheto wemukati weE kuita denderedzwa kuti urase marara kunze.

Processing nzira

1) Shaft nhoo dzinofanirwa kugadzirwa pamberi pekugadzira.Basa guru remudziviriri we shaft ndeyekuvhara gomba remukati remukati-rakatetepa sleeve nehukuru hwepakutanga uye kuigadzirisa nechemberi uye nechekumashure, kuitira kuti igone kugadzirisa denderedzwa rekunze pasina deformation, uye kuchengetedza hutano hwekugadzirisa. uye kururama kwedenderedzwa rekunze.Naizvozvo, kugadziridzwa kwekuchengetedza shaft ndiyo kiyi chinongedzo chetete-walled casing processing.

45 #carbon structural round simbi yekugadzirisa rough embryo yekuchengeta shaft;Tenderedza chiso chekupedzisira, vhura maburi epakati akaita B pamativi ese maviri, ita denderedzwa rekunze rikashata, uye siya 1mm mvumo.Mushure mekupisa kupisa, kudzima uye kupisa, kugadzirisa, uye kutendeuka kwakanaka, mvumo ye0.2mm ichachengeterwa kugaya.Iyo yakapwanyika murazvo wemoto ichave pasi pekupisa kupisa zvakare nekuoma kweHRC50, uye yobva yagayiwa necylindrical grinder, sezvakaratidzwa mumufananidzo unotevera.Kurongeka kwacho kuchave kunogutsa uye kuchawanikwa nyore pakupedza.

2) Kuti upedze kugadziridzwa kweiyo workpiece panguva imwe chete, iyo rough embryo inofanirwa kunge ine clamping chinzvimbo uye yekucheka mvumo.

3) Chekutanga, mushure mekupisa kupisa, kupisa, uye kuumbwa, kuoma kwemvere embryo ndeye HRC28-30 (mukati meiyo machining range).

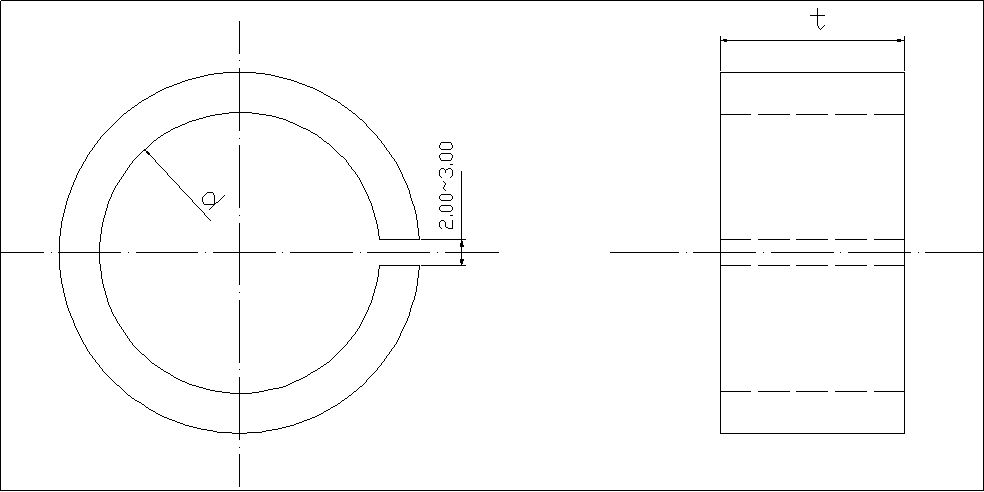

4) Chishandiso chekushandura chiri C620.Chekutanga, isa nzvimbo yekumberi mune spindle cone yekugadzirisa.Kuti udzivise deformation yeworkpiece kana uchisungirira sleeve yakatetepa-yakavezwa, yakavhurika-loop gobvu sleeve inowedzerwa, sezvinoratidzwa mumufananidzo unotevera.

Kuti uchengetedze kugadzirwa kwehuwandu, imwe mugumo wemhete yekunze yeganda rakatetepa-yakakomberedzwa inogadziriswa kuita saizi yakafanana d, mutongi anosungirirwa axially, uye ganda rakatetepa-rakakomberedzwa rinomanikidzwa pakutenderedza gomba remukati kuvandudza kunaka. uye chengetedza saizi.Tichifunga nezvekupisa kwekucheka, zvakaoma kuziva kukura kwekuwedzera kwe workpiece.Yakakwana yekucheka fluid ichaiswa jekiseni kuti ideredze thermal deformation ye workpiece.

5) Batanidza workpiece ine otomatiki inoisa matatu shaya chuck, tenderedza yekupedzisira kumeso, uye rough muchina denderedzwa remukati.Iyo yekupedzisa kutendeuka mvumo ndeye 0.1-0.2mm.Tsiva iyo yekupedzisa kutendeuka chishandiso kugadzirisa iyo yekucheka mvumo kuti isangane nezvinodiwa zvekuvhiringidza kukwana uye kushata kweiyo inodzivirira shaft.Bvisa buri remukati rekushandura chishandiso, isa shaft yekurinda pakati pepamberi, woisungirira nepakati pemuswe zvinoenderana nehurefu hunodiwa, tsiva iyo cylindrical inotenderedza turusi kuita rough iyo inotenderera, uye wozopedzisa kutendeuka kuti usangane nezvinodiwa zvekudhirowa.Mushure mokupfuura kuongorora, shandisa banga rekucheka kuti ucheke maererano nehurefu hunodiwa.Kuti uite kucheka kutsetseka kana workpiece yakabviswa, chidimbu chekucheka chichave chakarereka uye pasi kuti chiite chiso chekupedzisira chebasa rekushanda;Chikamu chiduku chemurindi wevarindi chinoshandiswa kucheka gomba uye kuchikuya chiduku.Iyo yekudzivirira shaft inoshandiswa kuderedza deformation ye workpiece, kudzivirira vibration, uye kucheka zvikonzero zvekudonha nekuputsika.

Kkubatanidza

Iyo iri pamusoro yakatetepa-walled casing processing nzira inogadzirisa dambudziko rekuti iyo yakatetepa-yakavezwa casing deformation kana saizi uye zvikanganiso zvechimiro hazvigone kuzadzisa zvinodiwa.Iyo tsika inoratidza kuti iyi nzira ine yakakwirira machining kunyatsoita, uye kushanda kwakaringana, uye yakakodzera machining marefu uye matete emadziro zvikamu.Saizi iri nyore kugona, uye kugadzirwa kwebatch kunonyanya kushanda.

Nguva yekutumira: Sep-29-2022